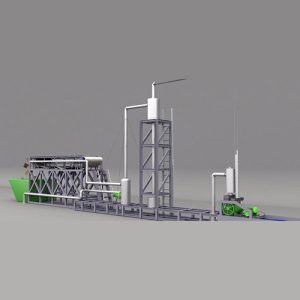

Liquid Ring Vacuum Pumps

Liquid ring vacuum pumps are used for operating vacuum levels up to 33-44 mbara, depending on liquid ring temperature. They provide high reliability because of their simplicity.

These types of pumps are normally used to handle gas mixtures that contain condensable vapours and various gases.

When the vacuum pump impeller rotates, the centripetal force creates a liquid ring concentric to the periphery of the protective cover, which facilitates the compression.

Reviews

There are no reviews yet.